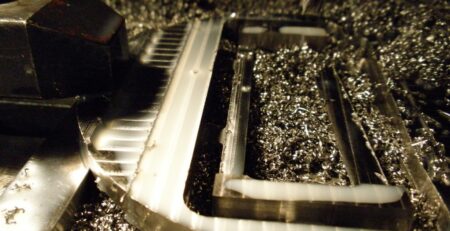

Extruder mechanism upgraded: Bondtech Dual Drive

Since early July, we have a had a very successful working relationship with Bondtech, the Swedish company producing Dual Drive extruders. The Bondtech extruders without question have brought a step change in reliability of extrusion. Main characteristic of course is the driving mechanism used: Twin counter rotating hobbed wheels.

Bondtech produce their own design of gear, and do not just take some generally available stock cut to size, meaning they control the material used, the hardness and ultimately the quality. Doing small batches at a time also ensures that the teeth in the hob are razor sharp. With good materials and design the user can expect long service life. The modular design on the other hand also allows replacement of wear parts without huge expense.

The problem that the extruders solve is that of filament grinding after repeated retractions. Those that have used flexible filaments or printed parts with perforations will know what pain it can be.

Bondtech extruders have been very popular with customers that print loads. So of course they are the natural upgrade to the BCN3D Sigma.

Different printers need different mounting hardware and Bondtech do provide some STL’s and ready parts for the Ultimaker. We did however design and produce our own mounts for the Sigma.

The mounts are made up of two parts, hindged at the bottom to allow quick and easy installation and disassembly. The original Sigma srews and nuts are retained of course.

Mod-up Time

We have kindly been allowed to describe one of the more innovative use of the Bondtech extruders, as shared on social media.

We are very proud to have supplied @IDeveloUK with his set of extruders and that he has still made use of our clamping mounts. IDevelo initially printed a mount that used the Bondtech supplied mounting hardware and held the extruders in the middle of the top rear lip of the Sigma.

His latest masterpiece, which has had very good reception from so many on Twitter, splits the two extruders, bringing them close to the edge and makes changing filaments a breeze. Colours of course are also very cool.

Another user and long time Sigma owner, @Chimpusmaximus has sent us photos of his first setup with the extruders mounted inside the Sigma, replacing the original placement and some photos of his external upgrade too:

We will be running a special purchase for the owners of BCN3D Sigmas which includes our design of mounting hardware, a left hand and right hand extruder and two pre-assembled cables to ensure plug and play assembly.

Kits however include a small upgrade for the owners of the ever popular Wanhao i3 Duplicator that keeps on impressing us and of course the impressive kit for the Raise 3D printers. i3 owners can also benefit from our Igus bearing kits and of course our own brand Nema17 dampers.

The new Bondtech extruder owners will need to tweak the peak current of the stepper motor and also the steps per unit of the stepper motor.

Interested in reselling extruders? Drop us an email

Error: Contact form not found.

Leave a Reply

You must be logged in to post a comment.