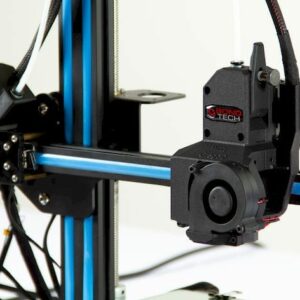

Bondtech BMG-M Extruder for Mosquito hotends

£70.83

Select Currency:The BMG-M has been specifically made for use with the Mosquito hotends by Slice Engineering. Of course there are still the 2 counter rotating hobbed gears so slipping and grinding is a thing of the past! DOES NOT contain the motor or mounting hardware. The hotend attaches to two screws on the underside for easier nozzle swaps.

Both righthanded and lefthanded now in stock!

- Description

- Additional information

- Reviews (0)

Description

The BMG-M has been specifically made for use with the Mosquito hotends by Slice Engineering. Of course there are still the 2 counter rotating hobbed gears so slipping and grinding is a thing of the past! DOES NOT contain the motor or mounting hardware. The hotend attaches to two screws on the underside for easier nozzle swaps.

Newer Mosquitos will have two cutouts on the top that will couple with antirotation features on the underside of the BMG-M

The Bondtech BMG utilizes an internal gearing ratio of 3:1 together with precision CNC-machined hardened steel drive gears to give you a compact powerhouse of an extruder. It is not the torque that typically lets printers down when it comes to extrusion but more the resolution available. Even microstepping can only go so far.

Bondtech Dual-Drive

The unique Dual-Drive technology delivers uninterrupted material flow without fear of grinding or slipping in even the most demanding conditions. Bondtech users the world over will attest that even in prints with thousands of retracts our extruders perform flawless, with unmatched precision, and zero damage or degradation to the filament.

Multi-material capability

The BMG extruder feeds all materials with high reliability, from slippery nylons and soft TPU/TPE filaments to highly rigid and sometimes brittle carbon-filled high-strength materials. The extruder is designed for 1.75 mm filaments, but has been tested to ensure performance of filament from 1.5mm up to 2.0mm allowing for high reliability regardless of the tolerance of the filament used. The filament path is fully guided throughout the extruder body and the housing maintains tight tolerances to the drive gears mitigating the chances of Filament Misfeed when the hotend experiences increased backpressure or highly flexible filaments are used.

Adjustable tension

The thumbscrew tensioner allows the user to fine-tune the pressure exerted by the drive gears onto the filament. This gives you the power to adjust according to your preferences and to optimize for the type of material you are using.

Quick-Release

To be able to do material changes in a snap, simply activate the Quick-Release lever to release the tension and pull the material to be changed out of the extruder, keep it activated and insert the new material.

Multi-application design

This new extruder can be used in a Bowden or direct setups and gives you the flexibility to choose what works best for your application. In addition it features an integrated hotend retention method compatible with the E3D-V6 hotends or others using the GrooveMount standard. Mounting your hotend is simple, secure, and wobble free by means of just two bolts.

The extruder can use any Nema17 motor with a standard 5 mm shaft.

Weight without motor: 75g

E-step value: 415

-

Sale!

Select optionsQuick View

Select optionsQuick View -

Sale!

Select optionsQuick View

Select optionsQuick View

Additional information

| Weight | 0.300 kg |

|---|---|

| Side | Right handed, Left handed |

Be the first to review “Bondtech BMG-M Extruder for Mosquito hotends”

You must be logged in to post a review.

Reviews

There are no reviews yet.