3D Printing

3D Printers and Printing

It has been mentioned everywhere so it is pretty much a mainstream nowadays but when we first started in 3D printing, it was still pretty fresh.

3D Printing has enabled hobby users and engineers alike to realise their designs with a significantly lower investment both in money and in time. This does not displace the need for traditional means of manufacture, but it does make prototyping and small series manufacture economical and accessible. At Emvio Engineering, the technology has enabled us to solve problems such as those caused by obsolescence or discontinuation of support by an original manufacturer. We have even helped biotech companies design and manufacture prototypes!

However we look at it, 3D Printing with machines sub the £100k mark still requires a lot of input from the user and understanding some of the intricacies of materials and the 3D Printing process is vital. As such at Emvio we have made the decision to only supply machines that we can support 100% and are known for their reliability. It took us a while for instance to start with resin printers. Our own personal favourite FDM machines are the Craftbots due to their true plug and play nature and the great working relationship we have with them.

-

Sale!

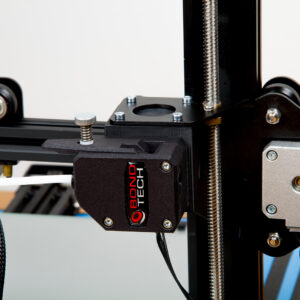

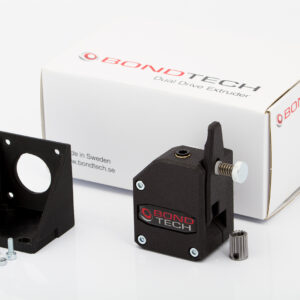

Select optionsQuick ViewCreality, Bondtech, Filament extruders, 3d Printer components

Select optionsQuick ViewCreality, Bondtech, Filament extruders, 3d Printer componentsBondtech Creality CR-10 and CR-10S kit

£75.00 – £79.17Select optionsQuick View

To ensure the best printing experience, we have also worked closely with a EU based company to make our own filament brands. Both the cosmetic range encompassed in our Chroma brand and the Technical range within the Techna brand have been well received and we are particularly proud of our PLA, Carbloaded PET ASA-EP and very much so about our soluble support Enabler and Enabler-HT.

Carbload PET was even featured on Joel Tellings 3D printing YouTube Channel!

As Emvio Engineering has its roots in conversion of manual machine tools into CNC and building machines, we have always been interested in improving 3D Printers too. Building or modifying a machine is actually made possible by the great body of knowledge available on the net and the Open Source nature of most companies. One of our most valued and longstanding partnerships has been with Bondtech of Sweden. Bondtech have been very influential in the 3D Printing world through their design of extruders. The likes of Prusa, Raise3D and BCN3D have all adopted original Bondtech extrusion technology while some Chinese manufacturers have tried to copy them. We are proud to say we have also assisted in the developement of some kits. BCN3D took that one step further and used our legwork to improve their designs significantly.

Selecting the best quality Extuders, hotends and nozzles are all crucial in improving your 3D Printer or creating a top machine. For this reason, we have also brought to the UK and European market the Olsson Ruby nozzles and the Mosquito Hotends by Slice Engineering. Each of these components is what you would call “Premium” but then again, they are money well spent.