Bondtech Creality CR-10 and CR-10S kit

£75.00 – £79.17

Select Currency:Not much to say about the Bondtech Creality CR-10 and CR-10S kit… apart from that it will massively improve the usability of the printer! As standard the CR-10 range of printers offer a very good value but have always suffered from the usual filament feeding issues. Bondtech came to the rescue as usual and have developed the kit to get you printing without grinding and improving your likelihood of being able to print TPUs.

These are made to order, please allow up to 7 days.

Please select your machine version in the dropdown box, reminder that the CR-10S has an inbuilt filament sensor.

Get the installation manual here

- Description

- Additional information

- Reviews (1)

Description

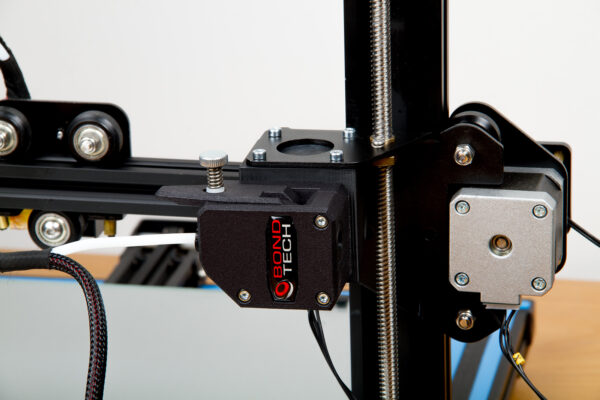

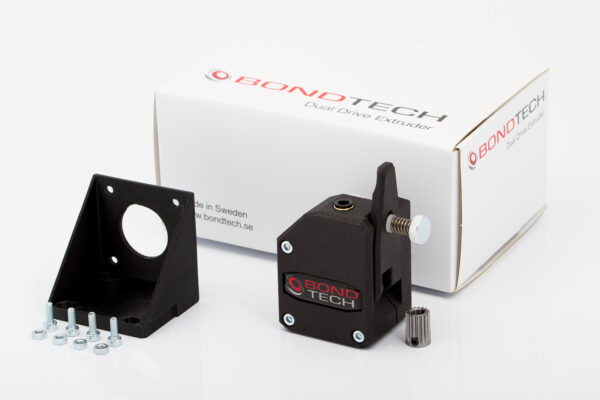

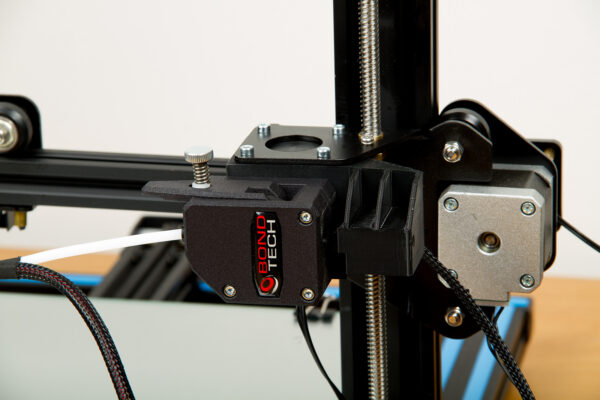

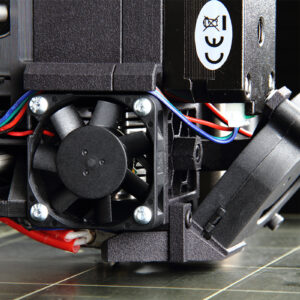

Based on the BMG dual drived and geared extruder, this kit will solve your CR-10 feeding and grinding problems and will also give you higher resolution that will improve surface quality. It will also allow to print faster with sustained quality and no risk for grinding the filament.

The lightweight BMG extruder features a 3:1 gearing ratio combined with the standard DualDrive precision cnc-machined and hardened steel gears for maximum performance.

- The kit with the extruder and a printed mount for CR-10.

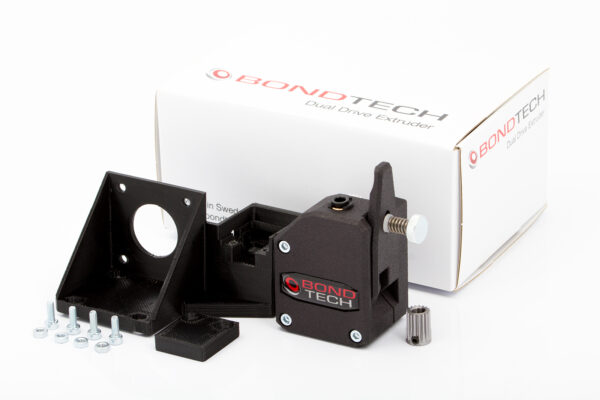

- The kit with the extruder and a printed mountfor CR-10S that houses the filament sensor

If you only want to purchase the BMG and print your own mounting hardware, please purchase a “BMG with Motor” and a “4mm bowden tube adapter”

E-steps needs to be updated to 415, please see the installation guide of how to do it. Rotation direction of the stepper motor needs to be changed (Installation guide)

This kit contains no motor, the original motor is used.

Additional information

| Weight | 1 kg |

|---|---|

| Version | Standard CR-10, CR-10S with sensor |

1 review for Bondtech Creality CR-10 and CR-10S kit

Add a review

You must be logged in to post a review.

Andrew Howat (verified owner) –

Really simple upgrade – takes about half an hour to do. The fiddliest part is switching around the two contacts in the stepper wires to reverse the direction of rotation!

But this makes a BIG difference to printing. Feeding is a lot smoother, clicking (even with fussy or bad filaments) is a thing of the past, and the results show exactly why printer manufacturers like Prusa and BCN3D are adding dual drive bondtech gears as standard to their extruders.

A few people might be thinking whether its worth it when the printer is so cheap anyway – but if you’re using the CR-10’s MASSIVE build volume to the maximum – then do you really want to find a print fails X days in because the stock extruder jammed?

Also, for an easy way to update the E-steps in marlin, run this set of gcode in Printrun (Prontrface) or in a gcode file:

M501 ; load EEPROM settings

M92 E415 ; set the Extruder steps to 415

M500 ; save EEPROM settings

that should save the settings on recent versions of Marlin without having to set it each time in your slicer!