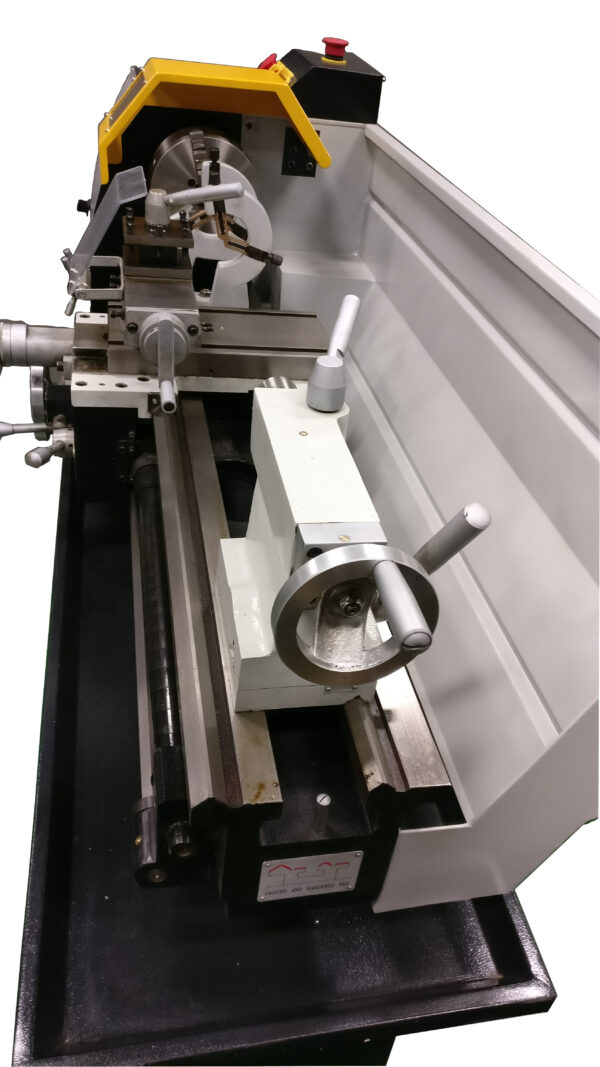

EML-290 Bench Lathe, 1.5kW Motor and Power Crossfeed

£1,958.33

Select Currency:They are here! Shipping as of 10th May

Want to get the best performance in your hobby machine shop? Have the space for a proper sized lathe? Then this is a perfect machine for you. The EML-290 bench lathe boasts, powered crossfeed, a inverter driven 1.5kW spindle, 3 ratio gearbox and Camlock Chuck!

- Description

- Additional information

- Reviews (3)

Description

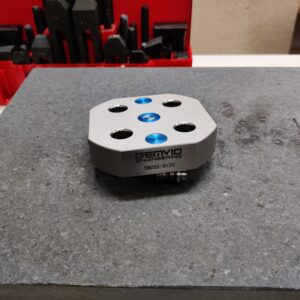

Also now available with 2 Axis DRO!

Our first lathe was a dinky little thing with a 750W motor and 300mm between centres. It paid itself off within a couple of years making parts for our flexible oil return hoses, but only after we upgraded the motor to 3-phase and drove it off an inverter. So as you can image we looked hard to find a supplier that would be able to supply a good machine to our spec, and now we have the EML-290 manual lathe. A machine aimed at the serious home workshop with the space and the need for larger diameters and lengths.

The EML-290 boasts a massive 38mm (approx. 1.5″) spindle bore with a MT5 taper, 290mm swing over bed (11.4″) and 700mm (27.5″) between centres. Suffice to say, there is plenty of room for most workpieces on this machine.

As standard, the EML-290 comes with a full package of accessories: Fixed and travelling steadies, dead centres, face plate, 4 jaw chuck, all the tools you would need and of course the key to the CamLock chuck!

Screw cutting is a breeze with this machine as is facing off thanks to the integral screwcutting gearbox and the power crossfeed. The latter runs of a secondary shaft, just like on industrial machines.

We have stock of stands and wedge type quick change tool posts. A DRO can also be supplied fitted or for retrofit upon request.

This machine really does boast some other cool features too, for example it has a dovetailed cross-slide to allow fitment of a rear toolpost, or a vice! It is also ready to accept an auxiliary milling head too.

Obviously, no self respecting turner would tolerate anything less than a lever locking tailstock.

| Model | EML-290 (based on SP2129) |

| Max. Swing over bed | 290 mm |

| Distance between centers | 700mm |

| Swing over cross slide travel | 180mm |

| Width of bed | 182mm |

| Spindle taper | MT5 |

| Spindle hole | 38mm |

| Range of spindle speed | 50-1800r/min |

| Range of cross feed | 0.01~0.10mm/rev |

| Range of longitudinal feed | 0.085~0.832mm/rev |

| Range of Imperial thread | 8~56T.P.I |

| Range of Metric thread | 0.2~3.5mm |

| Top slide travel | 65mm |

| Cross slide travel | 160mm |

| Tailstock quill travel | 70mm |

| Taper of tailstock quill | MT3 |

| Motor power | 1.5kw – with 1Phase to 3Phase inverter |

| Packing Size (L*W*H) | 145*70*68cm |

|

Net/Gross weight |

260kg/280kg |

Additional information

| Weight | 250 kg |

|---|

3 reviews for EML-290 Bench Lathe, 1.5kW Motor and Power Crossfeed

Add a review

You must be logged in to post a review.

Lee Roebuck –

For a kick off this machine is alot bigger and “more machine” than i was expecting. I work on colchester 2880 and 1550 machines all day long and am accustomed to working up to 4ton, so when I tell you this is alot of lathe for this price you can be happy I know my lathes. I have this machine stood in my own home workshop now and it will happily run up to full speed and stay there with no issues. the array of extras such as the 4 jaw and steady that come with it are all sweet as a nut and the whole thing feels solid and quality. You can’t argue with the size of the spindle bore at this price, I really struggled to find better.

As i mentioned in my other review of emvio’s mill, these guys are always happy to help with special delivery instructions and installation questions and have genuinely become friends of mine due to their kind nature. If you want to buy a machine off a company that will genuinely take care of you and your needs, you can’t go wrong here.

Bucky

Metal Monastery

andy Biddle (verified owner) –

Could have been better, as the handling was a bit shoddy. The protective cover was damaged with some paint chipped but not excessively. George was very helpful, I did replace the studs as they were bent. George did say he’d recompense me but I thought he had done enough with sending the dial indicator for screw threading. A very pleasant experience.

George (store manager) –

Hi Andy!

Thank you so much for your review, really sorry your machine was not 5 star worthy like I want all my machines to be. We will definitely be improving on handling and of course, you can always count on us to make things good.

Looking forward to seeing some of your builds in the future too.

Keep well

Jeff N. (verified owner) –

I could not fault the friendly service. The machine is performing to specifications great fun. small issues were easily dealt with. Look forward to the time I can purchase a mill to go with it. Thanks from Jeff good value for the money.

George (store manager) –

Jeff, you are most welcome! Thank you for your purchase and your time writing your review.