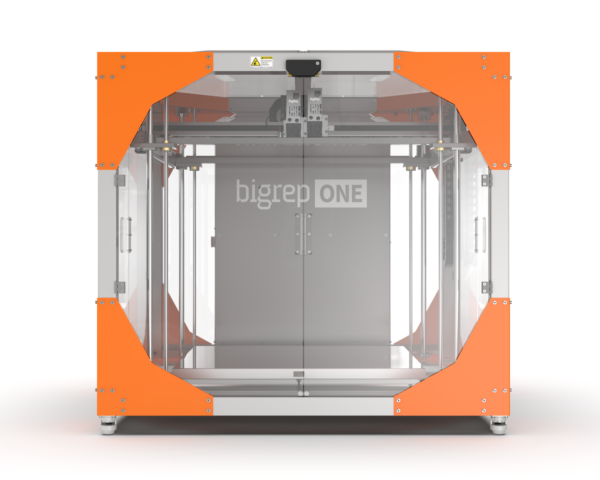

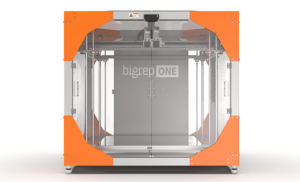

BigRep ONE – Large scale 3D Printer

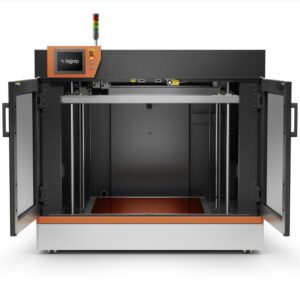

Select Currency:When it comes to printing big, the award winning BigRep ONE is STILL the go to industrial solution. With a true build volume of 1m3 3D printing can take on a totally new dimension. Now enclosed and more space efficient too!

Get in touch with us for more information!

- Description

- Additional information

- Reviews (0)

Description

Yes, Emvio Engineering is a UK based Bigrep sales Agent.

The driving force behind the BigRep ONE hasn’t changed: make large-scale 3D printing affordable and available to more users. To achieve the best possible conditions for printing large objects a lot of new features are being introduced.

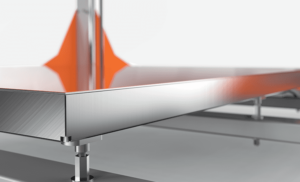

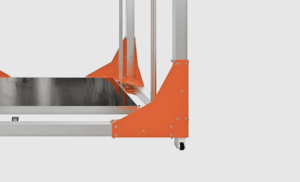

To achieve the best possible conditions for printing large objects, a lot of new features have been introduced to the latest version of the BigRep ONE large scale 3D printer. The modular print heads have been completely redesigned, in combination with a larger flexible spool holder, this provides the ideal 3D printer for manufacturing large-scale objects. The open format allows the user to have the best view for monitoring the print process. For large scale prints, our new high throughput extruder for 1 and 2mm nozzles allows for the highest throughputs, making the BigRep ONE v3 one of the fastest large-scale 3D printers on the market.

FEATURES

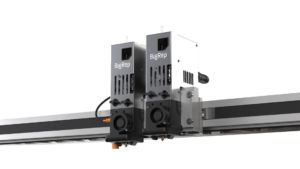

Developed by BigRep’s in-house team and optimised for large-scale printing projects, BigRep’s fiber-ready Power Extruder (PEX) is available for single or dual extrusion. During the printing process, the inactive head retracts to avoid collisions. The modular print heads operate independently, allowing for unbeatable flexibility when printing in two colours or materials. Adjustment and replacement is tool-less too!

It consistently produces high-quality, full-scale parts in a range of BigRep filaments such as bio-polymers, water-soluble support, and fiber-reinforced, as well as third-party materials. Featuring interchangeable 0.6, 1.0, and 2.0 mm nozzles for maximum detail or high-flow additive manufacturing, the BigRep Power Extruder is a flexible solution for a variety of applications.

Construction

This giant mould was printed with the BigRep ONE for the Geiger GmbH, a german construction company based in Ansbach. It was used to rebuild the lintels as part of the buildings renovations. It enabled the client to save time and material.

Sand Casting

Traditionally, patterns are made manually using wood, filler and skill. The process is not ‘digital’, meaning it takes longer to complete and can result in accuracy issues, not to mention is not necessarily repeatable. Enter large scale 3D Printing! Now complex shapes such as propellers can be sand or even investment cast in the fraction of time and cost.

Protoyping

with the large scale print format any designer can now become their own fabricator too. Full scale furniture is only the beginning.

Error: Contact form not found.

Additional information

| 3DPrinting Process | FDM/FFF |

|---|

Be the first to review “BigRep ONE – Large scale 3D Printer”

You must be logged in to post a review.

Reviews

There are no reviews yet.