The Benefits of 3D Printing With Carbon Fibre

As 3D printing technology continues to evolve, so too does the range of materials that can be used in the process. One of the most exciting developments in the industry is the emergence of carbon fibre 3D printing, which has the potential to revolutionise the way we manufacture products. With its remarkable strength and light weight, carbon fibre is becoming the material of choice for 3D printing, offering a wide range of benefits for both designers and manufacturers. In this blog post, we’ll take a closer look at why carbon fibre 3D printing is the future of manufacturing.

Adding carbon fibre (CF) to filaments improves both strength and stiffness. The added strength and increased stiffness provided by the addition of CF leads to a better strength-to-weight ratio, achieving lighter, stronger parts with less printing time.

“Industrial environments often demand specific mechanical properties and finely tuned precision. Fortunately, by bringing together the capabilities of a high-strength material and the many advantages of additive manufacturing, carbon fibre 3D printing offers exceptional dimensional stability in strong, stiff parts with a fine surface finish and a high heat deflection temperature – ideal for functional, high-performance applications.”

Whether using carbon fibre filament in molds, jigs, fixtures, tooling or high-performance race cars, aerospace or professional cycling, carbon fibre 3D printer filament enables you to create high-strength parts.

So what are the Pros of printing with CF?

HIGH STRENGTH

Carbon fibre offers a strength-to-weight ratio that enables high performance with low density.

DIMENSIONAL STABILITY

Carbon fibre’s high strength and stiffness are essential for parts that require precise dimensions and tight tolerances.

LIGHT WEIGHT

Using carbon fibre materials enables weight reduction without a loss of performance-grade strength.

HIGH HEAT DEFLECTION TEMPERATURE

Compared to standard 3D printing materials like PLA, ABS, and PETG, carbon fibre filaments can withstand significantly higher temperatures.

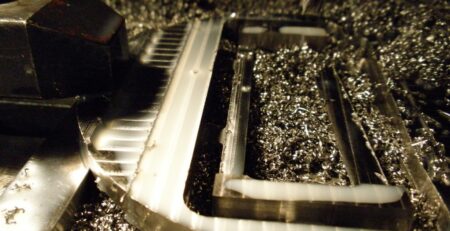

LESS POST-PROCESSING REQUIRED

CF filaments make layer lines less noticeable. This gives you better surface quality and haptics, reducing the need for any post-processing, like sanding.

STIFFNESS

3D-printed carbon fibre parts maintain their shape under high stress. The rigidity possible with carbon fibre ensures structural integrity.

Printing with carbon fibre allows you to produce best-in-class lightweight, durable, functional parts that can stand up to a variety of industrial uses with all the complexity in design that 3D printing has to offer.

Get in touch to learn how CF filaments can help to improve your production capabilities.

Leave a Reply

You must be logged in to post a comment.