New To The BigRep Range – The SHIELD Industrial Filament Dry Cabinet

New 3D Product Alert!

We're delighted to welcome the Calibry Mini 3D Scanner to our range.

The UK’s Biggest Event For Inspiring, Innovating And Connecting Manufacturing.

MACH 2022 IS THE UK’S BIGGEST EVENT FOR INSPIRING, INNOVATING AND CONNECTING MANUFACTURING.

Taking place from 4th-8th April, MACH will be the THE event to connect the world of manufacturing technologies.

MACH is a fantastic event for both exhibitors and visitors. Showcasing live, digital production systems under one roof. At Emvio, we consider MACH an important asset to the UK’s manufacturing sector, providing a platform for us to showcase our products and services, and a great opportunity to meet customers!

This year we are showing some amazing products, including....

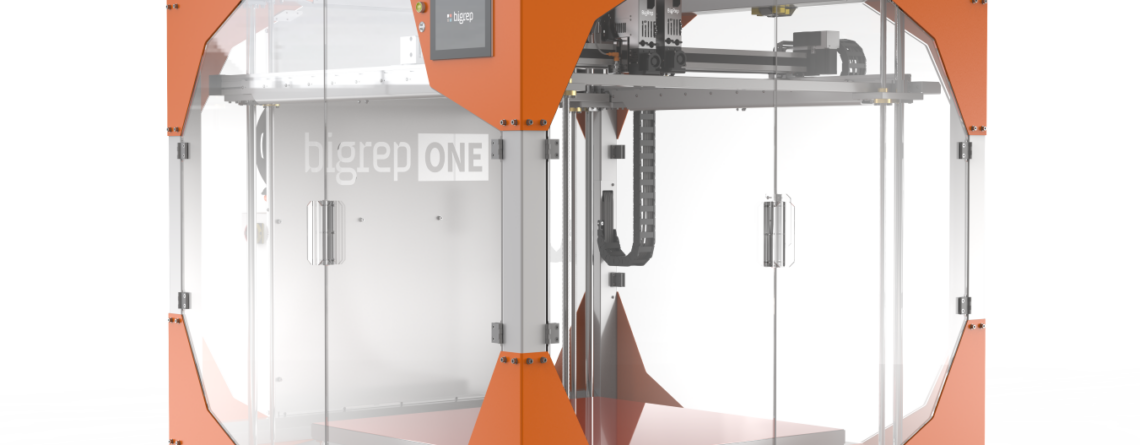

The BigRep ONE 2022 New Features!

Exciting times, European 3D printer that kicks ass!

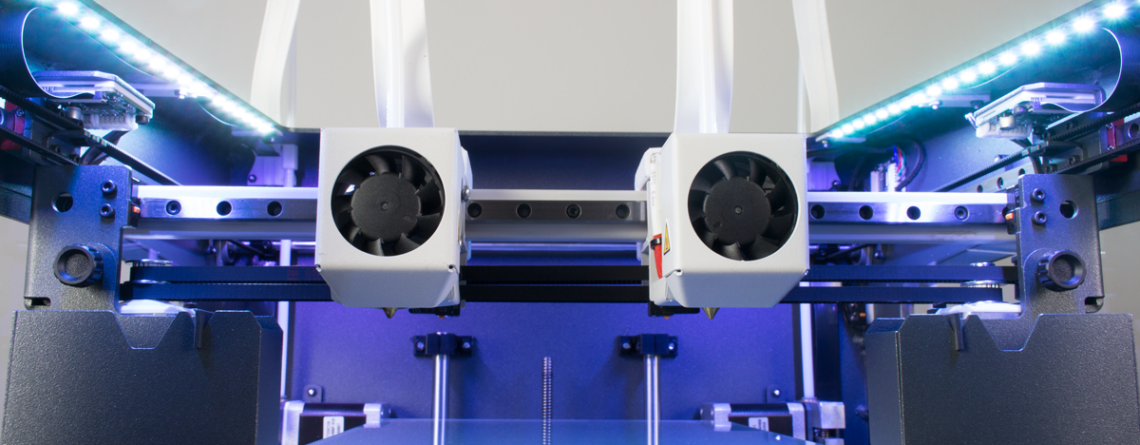

- Enclosed design with 210x297x210mm build volume

- Dual heads independent that park when not in use

- Profile linear rail, not round bar, on the axes!!!!!!!!!

- TOUCH SCREEN!!!

Quick change and repeatable Z tooling for MT3 and R8 spindles?

Industrial and hobby machinists alike all have the same pet hate when it comes to changing tools whether using a Bridgeport knee mill or a bench top CNC mill:

"It takes too long!"

Lets explore this topic and how Emvioeng.com will help small and large workshops alike become more efficient.

Web Browser based CAD? OnShape seems to think its OK

It is not often that the CAD industry gets shaken up as much as it has in the past 12 months. First we had Autodesk Fusion 360 coming out with a Cloud based service and we have recently received word of OnShape.

The pedigree of OnShape could not be purer, it is spearheaded by the founders of Solidworks, an industry favourite for as long as I can remember.