Pioneers in 3D Printing

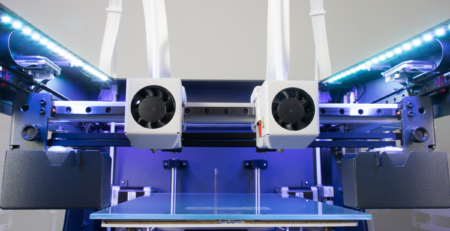

Bondtech, the dual extruder manufacturer

Bondtech develops, designs and manufactures unique dual drive extruders that eliminate the risk of grinding, slipping, filament deformation and under extrusion. Using two counter-rotating drive gears, the Bondtech extruders grip and push the filament from both sides for a secure and stable filament feed. The result is a reliable, more precise and faster printing process.

The company was established in 2014 by Martin Bondéus, who had previously used 3D printing technology in his work as a product developer. When certain patents regarding the FDM technology expired at the beginning of the 2010s, Martin set out to build a 3D printer based on a pre-designed kit. The result, however, wasn’t satisfying. The performance and quality just weren’t there. So, Martin started building his very own printer from the ground up. Only this time the result was much better, but unfortunately still not good enough. Grinding, slipping and under extrusion translated into several failed prints. Scouting the internet for advice, he realised that the problem with bad, unreliable extrusion was universal. Everyone seemed to suffer from the same dilemma. An idea was born.

“Constantly improving our offer, we believe this is just the beginning.”

Today, Bondtech manufactures Bondtech Dual Drive extruders and other innovative 3D printing products to users and retailers across the world.

Bondtech have understandably revolutionised the reliability and speed of printing using filaments. We are proud to be the UK partners to Bondtech since 2017.

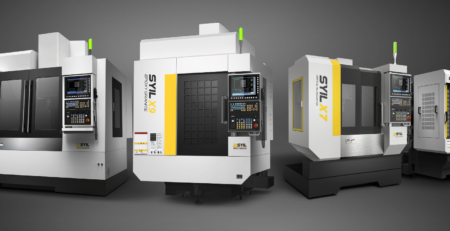

With rapid growth, Bondtech has invested in faster and more accurate CNC machines, bringing production of their products almost all in-house. Naturally they are very well versed in making small precise objects.

The next step in their evolution has been the production of their own Nozzle Range. Most spectacular one in their range is for sure the CHT series.

Advantages of the Bondtech CHT® technology:

- Higher melt capacity by increasing the surface area of the heating walls

- Affordable price

- Machined with ultra-precision

- Brass nozzle with Nickel coated surface

- Follows nozzle standards: RepRap (M6×1×7.5×12.5), MK8 (M6×1×5×13)

You can find our full range of Bondtech products here.

Leave a Reply

You must be logged in to post a comment.